RoboHive

Intuitive multi-robot programming for highly complex automation tasks

What is RoboHive?

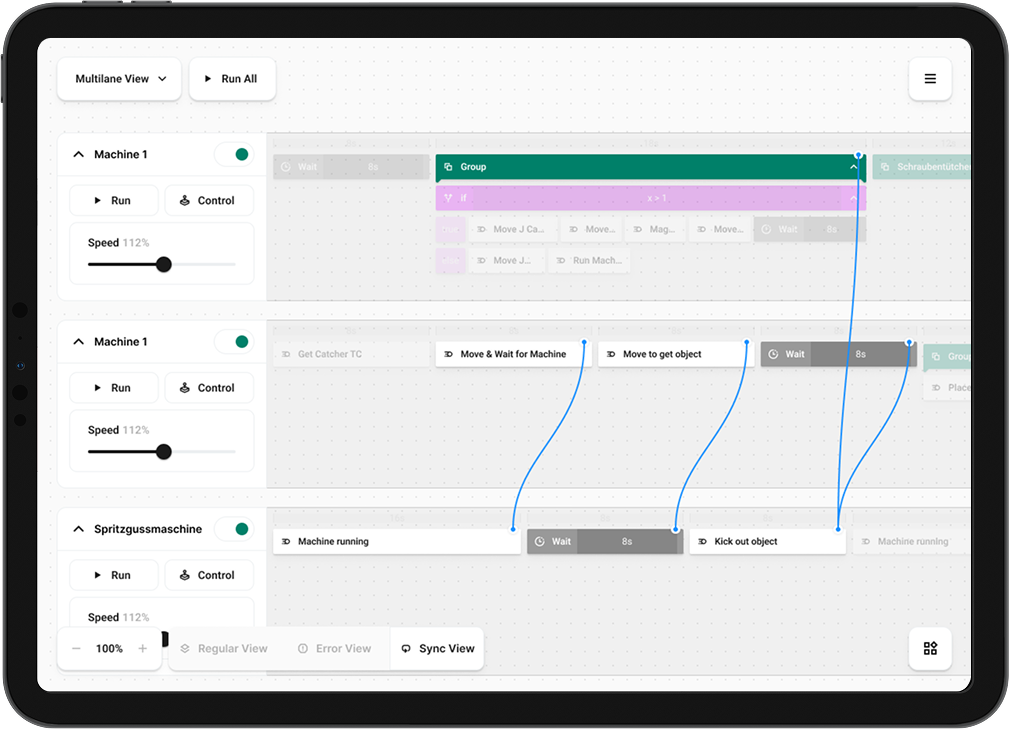

RoboHive is an innovative software for intuitive programming and control of robots and machines. With a unique, time-based drag-and-drop interface, RoboHive makes it easy to create, visualize and synchronize complex workflows across multiple machines. The integration of artificial intelligence, the flexible use of Python and comprehensive control functions make it possible to implement even sophisticated automation efficiently and transparently. RoboHive combines maximum user-friendliness with technical freedom and thus creates the basis for smooth, intelligent machine cooperation.

Cooperation between the machines

RoboHive offers powerful functions for coordinated collaboration between robots and machines to make processes reliable, safe and efficient.

Simple synchronization of robot and machine: RoboHive enables seamless coordination between robot systems and PLC-controlled machines. Signal states, process steps and time sequences can be organized in such a way that harmonious interaction is possible without manual intervention.

Safety zones and area blocking: For safe operation, defined areas within the robot cell can be blocked depending on time or status. This prevents robots from unintentionally entering active machine areas.

Complementary robot skills for collaboration: RoboHive supports the creation of skills that are specially designed for the interaction of several robots – for example for transferring objects or for mutual support during assembly or handling processes.

Transparent scheduling: The visual, time-based display of robot and machine actions makes the duration of individual steps visible at a glance. This facilitates the precise planning and synchronization of all systems involved in the overall process.

Use cases of RoboHive

RoboHive really comes into its own in robot cells with multiple components or multiple robots that need to work together precisely. Typical areas of application include complex tasks such as packaging products, assembly processes and kitting different components in variable combinations. The clear program structure, flexible synchronization mechanisms and support for natural language programming significantly simplify the control of even extensive automation scenarios. RoboHive ensures a fast, reliable and transparent setup, particularly in applications where precise coordination of processes, gripper controls and machine communication is required.

Artificial intelligence helps with programming

With the integrated AI assistant, RoboHive noticeably speeds up robot programming. Users can simply describe their tasks in natural language without having to worry about complex syntax. RoboHive automatically converts this description into an executable robot program and thus lays the foundation for the process flow. The generated program is fully editable and can be flexibly adapted to individual requirements. Targeted extensions and fine adjustments allow even complex tasks to be implemented quickly and efficiently. RoboHive thus combines the power of artificial intelligence with full control over the programming details.

Robot skills in RoboHive

RoboHive enables efficient and structured creation of reusable robot skills and subprograms to reduce development effort and increase flexibility in automation.

-

Creation of reusable robot skills: Users can define robot skills as stand-alone skills or sub-programs that can be used multiple times in different projects and applications. This makes programming more sustainable and easier to maintain.

-

Individual adaptation: Created program libraries can be flexibly adapted and integrated directly into the respective robot programs. Skills can be easily parameterized and tailored to specific applications.

-

Flexible integration of Python modules: RoboHive enables the seamless integration of external Python modules, allowing existing software solutions and in-house developments to be quickly incorporated into skill programming.

-

Integration of artificial intelligence: RoboHive offers the option of integrating your own AI models and algorithms in order to equip robot capabilities with intelligent behavior. This allows users to design customized, future-proof automation solutions.

Error handling in RoboHive

RoboHive offers powerful and intuitive error handling that significantly increases the reliability and safety of your robot applications. The most important functions at a glance:

Intuitive error management: RoboHive detects typical error conditions such as incorrect grips, components being dropped or collisions with machine elements, for example due to incorrectly gripped parts. Thanks to direct integration into the programming logic, any errors that occur can be quickly analyzed and rectified.

Clear structures for alternative programs and troubleshooting: Thanks to the clear, time-based display of program sequences, alternative paths and error handling can be created easily and comprehensibly. As a result, users always retain control over possible deviations in the process.

Background monitoring by watchdogs: Permanent monitoring of critical signals and variables is carried out by watchdog mechanisms. If defined thresholds are exceeded or anomalies are detected, the main program is safely interrupted. This allows timely intervention to prevent damage to machines, robot cells or components.

Flexible real-time commanding: In the event of an error, robot actions can be flexibly re-controlled in real time. This allows processes to be adapted dynamically without lengthy reprogramming.

Full use of Python libraries: RoboHive allows the connection of powerful Python libraries and integration into the internal communication structure. This means that error management can be individually expanded and adapted to complex requirements.

Robot control with RoboHive

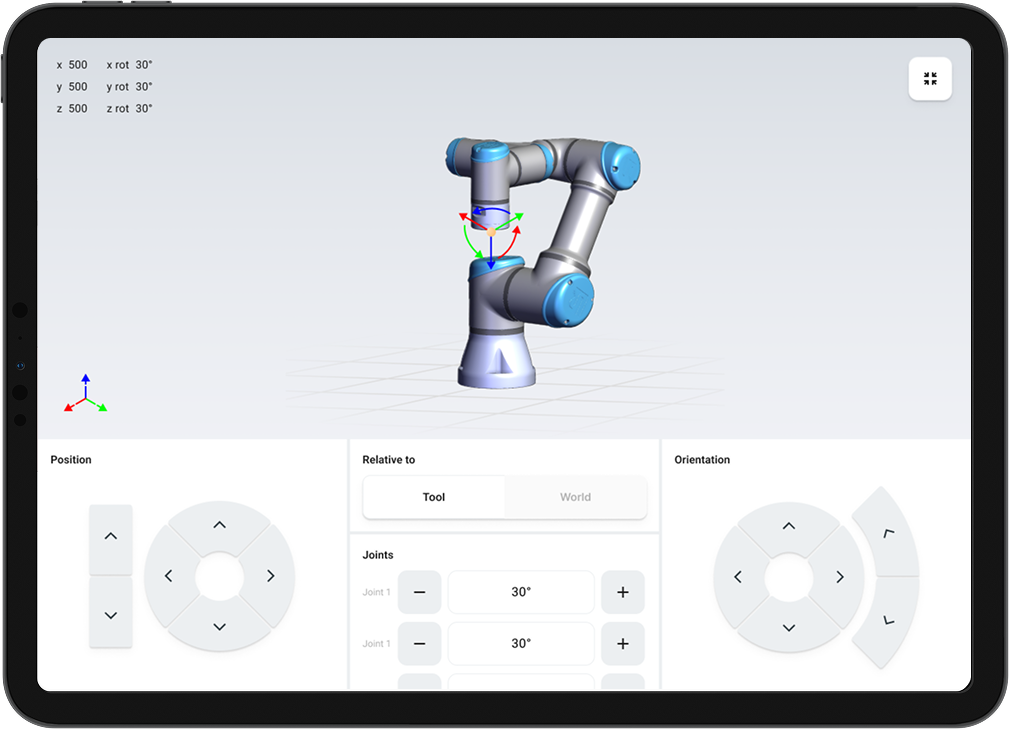

RoboHive offers comprehensive options for direct control of robots and their peripherals to ensure maximum precision and flexibility during commissioning and programming.

Direct commanding of movements: Robots can be controlled both Cartesian and directly via individual axes. This enables fast and precise alignment and adaptation to different working environments.

Fine control mechanisms for cobots: RoboHive offers precise fine adjustment functions especially for working with collaborative robots (cobots). Movements can be adjusted safely and with millimeter precision to achieve optimum results in sensitive applications.

Positioning in the virtual world: RoboHive allows the exact positioning and movement of the robot within a virtual environment. This supports the planning, simulation and optimization of work processes even before the real implementation.

Control of grippers and I/Os: In addition to robot movement, grippers, external actuators and robot inputs and outputs can also be specifically controlled via RoboHive in order to implement complex processes easily and flexibly.

How can we help you with your automation projects?

We look forward to supporting you with your challenges and automation projects.

Dr. Roman Weitschat

Managing Director (CEO)