We support you in efficiently automating complex and frequently changing tasks.

Intelligent Robotic Solutions for Advanced Manufacturing

Are you looking for an automation solution that keeps up with complex or frequently changing tasks?

We are happy to advise you – individually, without obligation, and solution-oriented.

With over 15 years of high-tech robotics experience at the German Aerospace Center, we are your trusted partner in modern automation.

Dr. Roman Weitschat

Chief Executive Officer (CEO)

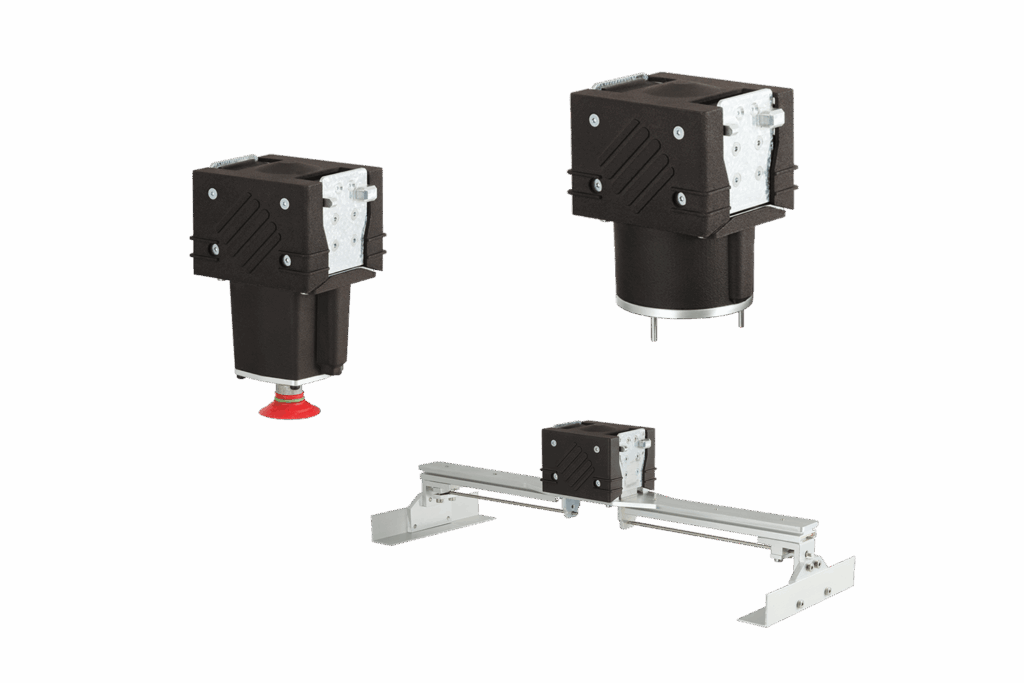

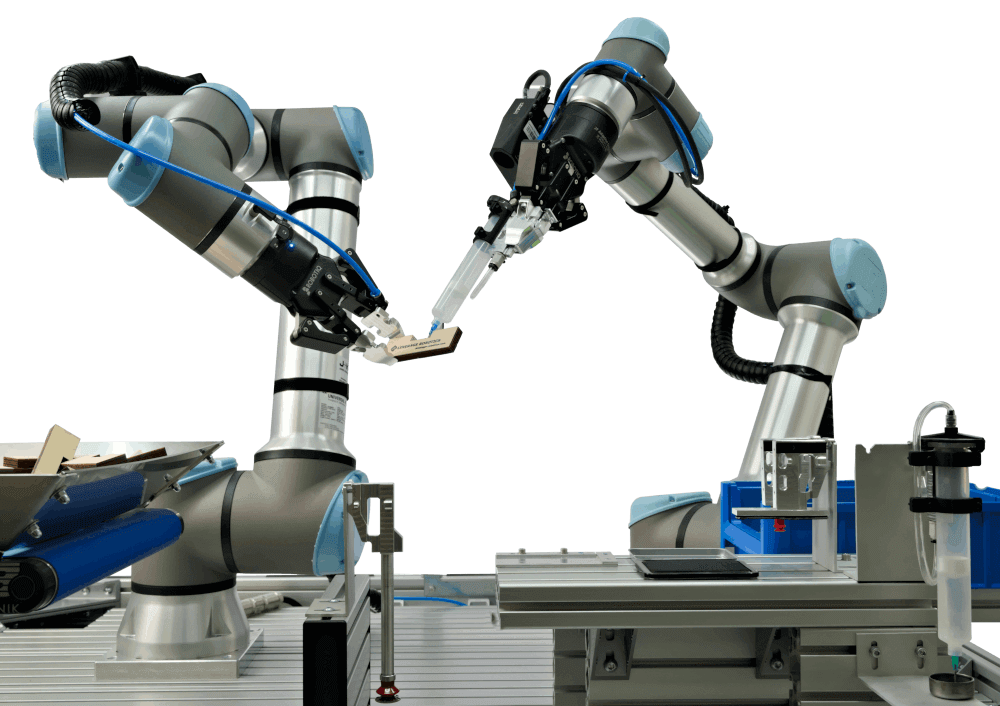

Tool Changing with ToolCubes

Efficient automation requires flexible tools. With our passive and active ToolCubes, we implement smart tool-changing systems for robots without additional energy or data connections.

- Planning and integration of passive and active tool changers

- Design of multi-tool strategies for flexible production processes

- Development of robust gripping and changing mechanisms

- Cycle time optimization through automated tool changes

- Consulting on integration into existing robot cells

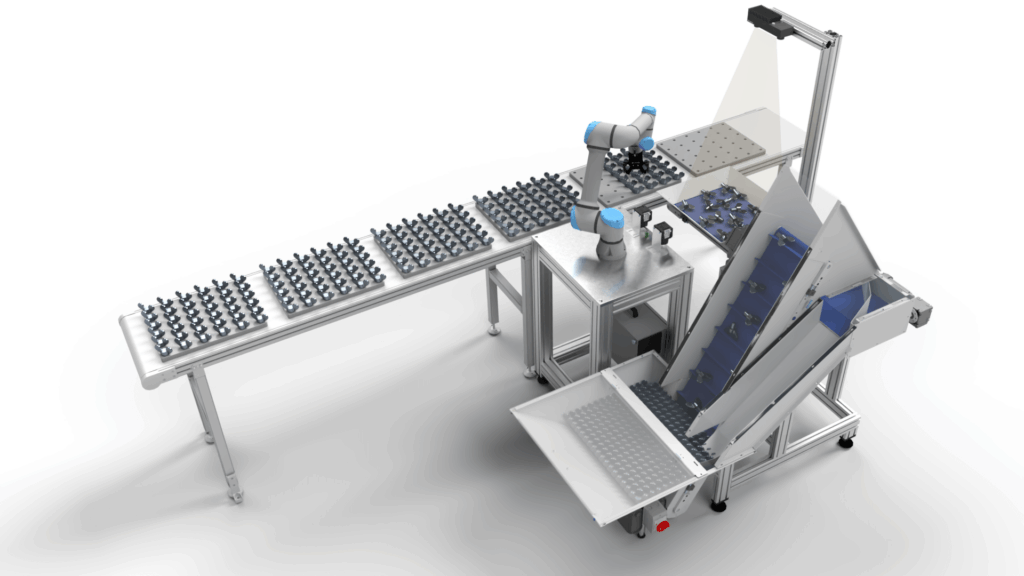

Flexible Component Handling

Different geometries, materials, and positions – we develop solutions for reliable gripping, singulation, and positioning, even with highly varied components.

- Analysis and design of flexible feeding and handling systems

- Selection and adaptation of suitable gripping technologies

- Use of intelligent image processing for position detection

- Development of robust strategies for bulk material handling

- Integration into existing processes and production lines

Automation of Highly Complex Processes

Many manufacturing tasks are too

diverse or complex for conventional automation. We help you automate

these processes efficiently with

innovative approaches.

- Process analysis and feasibility assessment

- Development of modular automation solutions

- Use of AI-assisted recognition and decision-making strategies

- Combination of sensors, robotics, and intelligent software

- Implementation of flexible robot cells for changing requirements

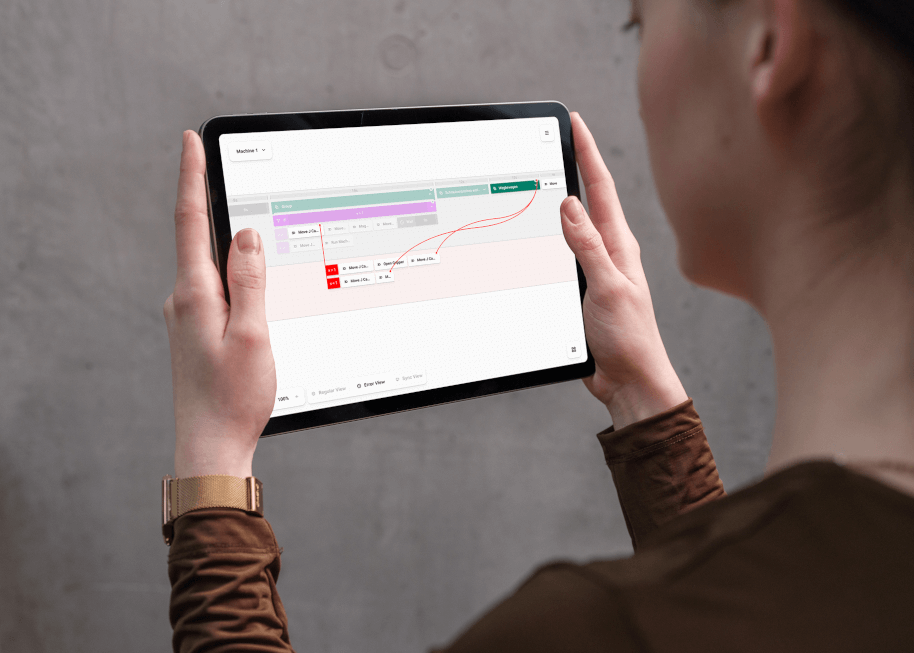

Intuitive Robot Programming

Robot programming doesn’t have to be complicated. With our expertise and our RoboHive software, we design automation to remain understandable for your employees and easily adaptable.

- Consulting on intuitive robot programming with RoboHive

- Development of user-friendly programming interfaces

- Support in standardizing workflows

- Training employees for easy adjustments

- Integration of low-code / no-code concepts into your production

Fields of Application

Dispensing / Gluing

Robot-based bonding and dispensing is revolutionizing precision manufacturing in industries such as automotive and electronics production. These automated systems use advanced robotic technology and precise control software to apply adhesives and sealants accurately and repeatably. They optimize production processes, increase throughput speed and guarantee consistently high quality standards while minimizing waste.

Maschine tending

Robot-based machine loading optimizes automation in production environments by increasing the efficiency and accuracy of material handling. Specialized robotic arms precisely load workpieces into processing machines, resulting in improved production speed and quality. This technology is ideal for industries such as automotive supply and precision manufacturing, where it reduces operating costs and increases workplace safety.

Assembly

Robot-based assembly systems transform manufacturing processes through increased precision and efficiency. These systems implement advanced robotic technology to automatically assemble components, ideal for complex and high-volume production lines in the automotive and electronics industries. They improve product quality, speed up production cycles and reduce labor costs while ensuring consistent execution.

Quality assurance

Robot-based quality assurance is revolutionizing production lines with automated inspection processes that increase precision and efficiency. This technology uses advanced sensors and AI-driven algorithms to enable real-time defect detection and analysis. Ideal for industries such as automotive, electronics and pharmaceuticals, it guarantees the highest quality standards and optimized operations.

Bin picking

Bin Picking is revolutionizing automation technology by enabling robots to pick randomly oriented objects from bins. This innovative solution combines 3D vision technology with artificial intelligence to optimize part recognition and handling in industries such as automotive manufacturing and electronics assembly and counteract labor shortages. Bin picking increases efficiency, reduces cycle times and minimizes the need for manual intervention.

Packaging

Robotic packaging systems or end-of-line automation increases efficiency in industrial production. These advanced systems, equipped with robotics and AI algorithms, optimize the final stage of production lines by packaging products safely and efficiently. Ideal for industries such as electronics, pharmaceuticals and manufacturing, they increase production speed, improve packaging quality and minimize manual effort.

Innovation for your company

Examples of robot automation with the ToolCubes, which are used for both cobots and industrial robots